Crucial Tips for Successful Welding Inspection Madison Providers

Crucial Tips for Successful Welding Inspection Madison Providers

Blog Article

The Significance of Thorough Welding Assessment in Industrial Applications

In the realm of commercial applications, the significance of meticulous welding evaluation can not be overemphasized. It plays an essential role in guaranteeing the structural integrity and durability of welded elements. Advanced non-destructive screening techniques allow for the early discovery of potential defects, such as splits and incomplete fusion, which, if left unattended, might lead to disastrous failings. Adherence to strict industry requirements not only assures top quality however also constructs customer confidence. As we discover the diverse benefits of persistent welding inspections, one need to take into consideration the broader ramifications on security, reliability, and cost-effectiveness in industrial operations.

Enhancing Architectural Integrity

When it comes to welding assessment in industrial applications, boosting architectural stability is extremely important. The primary goal of welding inspection is to make certain that the welds are qualified of birthing the expected stresses and lots they will certainly encounter in service.

The relevance of preserving architectural honesty in welded structures can not be overstated. Improperly executed welds can lead to catastrophic failings, resulting in pricey repair services, downtime, and even endangerment of human lives. Examiners play a crucial function in the lifecycle of commercial elements, giving assurance that the welding procedure delivers the preferred toughness and sturdiness.

Moreover, advanced modern technologies, such as phased array ultrasonic screening and electronic radiography, offer improved capacities in discovering potential weak points, enabling for rehabilitative steps prior to problems escalate. By focusing on the stability of welds through thorough assessment, markets can guarantee operational effectiveness and prolong the durability of their infrastructure.

Recognizing Welding Problems

Determining welding issues is a crucial element of guaranteeing the safety and security and reliability of bonded structures. These issues can jeopardize the honesty of the entire setting up and, if left unaddressed, may lead to tragic failures. Common welding issues consist of porosity, splits, incomplete combination, and undercutting. Each of these defects develops from details reasons, such as inappropriate welding methods, contamination, or inadequate heat control.

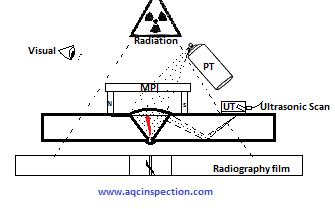

Proficient examiners use both aesthetic exam and progressed non-destructive screening (NDT) approaches, such as radiographic or ultrasonic testing, to discover these problems. The timely identification and correction of welding flaws are crucial to keep the architectural stability and durability of industrial components.

Making Sure Compliance Standards

Compliance with well-known requirements, such as those given by the American Welding Culture (AWS) and the International Company for Standardization (ISO), ensures that welds satisfy minimal safety and security and high quality demands. These standards encompass a wide array of requirements, including product requirements, welding procedures, and qualification of welders.

Routine audits and evaluations are important in validating conformity. Examiners have to possess why not try here a comprehensive understanding of the appropriate standards and be skilled at using numerous non-destructive testing visit (NDT) techniques to evaluate weld top quality. By making sure that welding practices line up with compliance requirements, firms alleviate the risk of non-conformity, which can cause legal responsibilities and safety dangers.

Moreover, preserving conformity not only safeguards structural honesty but likewise boosts a company's track record in the sector. Stakeholders and customers are more likely to trust fund firms that continually demonstrate a dedication to high quality and safety and security with strenuous compliance. Therefore, guaranteeing conformity requirements is a crucial part in the successful execution of welding in industrial applications.

Decreasing Upkeep Costs

The application of sophisticated non-destructive testing (NDT) methods, including ultrasonic, radiographic, and magnetic fragment evaluations, enhances the capacity to detect subsurface flaws without jeopardizing the structural stability of elements. By utilizing these methods, markets can considerably expand the service life of their tools, decreasing downtime and the associated monetary burden of upkeep activities.

Furthermore, a durable welding assessment program sustains the optimization of maintenance schedules, changing from reactive to anticipating maintenance strategies. This proactive technique not Get the facts just cuts unexpected failures however likewise simplifies resource appropriation, making certain that maintenance efforts are concentrated and effective. Inevitably, the financial investment in extensive welding inspection is countered by the considerable financial savings recognized via reduced upkeep needs, adding positively to the overall operational performance of commercial business.

Improving Precaution

Although safety is an extremely important problem in commercial operations, accomplishing optimum safety requirements requires a devoted concentrate on the quality and dependability of bonded structures. Welding examination plays a vital duty in this context, as it makes sure that all joints and links meet strict security standards. Comprehensive evaluations help recognize issues such as splits, porosity, or insufficient fusion that can endanger structural stability. Such flaws, if left unaddressed, position significant dangers, potentially causing catastrophic failings.

Techniques like ultrasonic testing, radiographic screening, and magnetic fragment examination enable for comprehensive assessment without harming the framework. Implementing a durable top quality control system that consists of normal training for assessors and welders makes certain adherence to established safety and security requirements.

Lastly, cultivating a society of security within the company highlights the importance of comprehensive welding inspections. Motivating open communication and collaboration among designers, inspectors, and welders adds to a common commitment to safety and security quality. Welding Inspection Madison. In doing so, sectors can guard their operations, safeguard personnel, and preserve public trust

Final Thought

Extensive welding examination is important in commercial applications, significantly improving structural integrity and integrity. By employing advanced non-destructive testing methods, possible welding problems such as splits and incomplete blend are recognized early, making certain conformity with industry criteria and promoting customer trust. Rigorous inspections lead to lowered upkeep prices and add to a safer working atmosphere. Inevitably, the thorough implementation of welding assessments plays a vital function in keeping operational performance and security in commercial settings.

As we discover the diverse advantages of thorough welding examinations, one must think about the more comprehensive ramifications on safety, reliability, and cost-effectiveness in industrial operations.

The main objective of welding evaluation is to guarantee that the welds are qualified of birthing the anticipated tons and tensions they will certainly encounter in solution. Effective welding assessment plays an important function in reducing these costs by making sure the integrity and long life of welds, thus minimizing the danger of premature failings.Detailed welding assessment is essential in industrial applications, dramatically improving structural honesty and dependability. Eventually, the diligent execution of welding assessments plays a vital duty in maintaining functional effectiveness and security in commercial setups.

Report this page