The Duty of Innovation in Modern Welding Inspection Madison Practices

The Duty of Innovation in Modern Welding Inspection Madison Practices

Blog Article

Comprehending the Basics of Welding Evaluation to Make Certain Top Quality and Security

In the world of modern design, welding examination stands as a cornerstone for ensuring both the quality and security of structural productions. The process entails a careful analysis of welded joints, employing sophisticated strategies such as ultrasonic and radiographic screening to find covert blemishes. The knowledge of certified inspectors is crucial, as they bridge the void between academic requirements and sensible application. Their duty extends past mere discovery, incorporating the documentation and communication of searchings for to appropriate stakeholders. Yet, what are the subtleties of these assessment techniques that make them essential for preserving architectural integrity?

Relevance of Welding Assessment

In the world of industrial fabrication, the importance of welding evaluation can not be overemphasized. Welding assessment plays a critical duty in ensuring the integrity, security, and longevity of bonded structures. Given the varied applications of welding in sectors such as construction, automotive, aerospace, and shipbuilding, the need for stringent quality assurance actions is critical. Appropriate examination ensures that welds meet specified standards and codes, which is essential for protecting against structural failings that can cause devastating consequences.

The process of welding inherently entails complex variables, consisting of temperature, material properties, and environmental problems, every one of which can affect the quality of the weld. A detailed examination identifies issues such as fractures, porosity, and insufficient blend, which can endanger the stamina and integrity of the weld. By discovering these issues early, rehabilitative actions can be taken, consequently reducing the danger of failing and linked costs.

In addition, welding evaluation adds to regulative compliance, as many sectors are governed by rigorous safety standards and guidelines. Failing to comply with these guidelines can cause legal liabilities and punitive damages. Eventually, welding inspection not only safeguards physical structures yet additionally shields human lives and upholds industry reputations.

Key Welding Examination Techniques

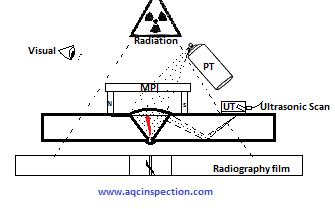

Although welding examination is vital to making certain the high quality and safety of welded structures, it is the details approaches used that figure out the performance of the assessment procedure. Trick welding evaluation approaches can be broadly classified into non-destructive testing (NDT) and damaging testing.

Ultrasonic and radiographic screening are advanced techniques that allow assessors to analyze the inner integrity of the weld. Ultrasonic screening uses high-frequency sound waves to spot interruptions, while radiographic screening employs X-rays or gamma rays to create a photo of the weld's interior. Magnetic fragment screening and liquid penetrant testing are surface examination approaches made use of to locate surface and near-surface imperfections. In comparison, devastating testing techniques include literally cutting the weld or damaging to evaluate its mechanical buildings. These detailed evaluation techniques make certain that welds fulfill sector standards and security needs, thus guaranteeing architectural stability and performance.

Function of Qualified Assessors

Qualified inspectors play a pivotal function in the welding examination procedure, ensuring that all welds adhere to rigorous sector criteria and safety policies. Their competence is crucial in recognizing problems or abnormalities that might endanger the structural integrity of a weld. By meticulously examining each weld, accredited examiners assist avoid possible failures that could cause costly repair services or harmful accidents.

To become licensed, assessors should go through rigorous training and screening, which acquaints them with various welding techniques, materials, and testing techniques. This thorough understanding allows them to review weld high quality efficiently and make notified judgments regarding their safety and security and reliability. Moreover, certified examiners excel in interpreting plans and requirements, guaranteeing that the welding work aligns with the job's layout requirements.

An indispensable part of their duty is to record their findings thoroughly, giving a thorough record of the assessment procedure. This paperwork is critical for traceability and responsibility, working as an official record of conformity with sector standards. Licensed inspectors additionally play a key duty in promoting interaction between task stakeholders, using insights and referrals to boost welding techniques and outcomes. Their payment is important in keeping high levels of top quality and security in welding procedures.

Devices Utilized in Welding Examination

Welding assessors count on a range of specialized tools to perform their responsibilities properly, making certain each weld satisfies the needed requirements. Amongst these tools, visual inspection help like amplifying glasses and mirrors are fundamental, permitting examiners to closely examine welds for surface area flaws such as cracks, porosity, and undercut. Calipers and fillet weld determines are crucial for determining weld dimensions to confirm compliance with layout specs.

Advanced devices prolong beyond aesthetic aids, consisting of non-destructive testing (NDT) tools. Ultrasonic testing tools are critical in spotting subsurface imperfections, utilizing acoustic waves to expose internal discontinuities without compromising the weld's honesty. Radiographic testing employs X-rays or gamma rays to catch photos of a weld's interior, highlighting prospective issues.

Magnetic particle screening is an additional vital device, particularly for finding surface and near-surface interruptions in ferromagnetic materials. By applying ferrous particles and magnetic fields, examiners can recognize defects that may or else be unseen.

Dye penetrant examination is frequently utilized for non-ferrous products, his explanation giving a contrast-enhanced visual check for surface-breaking problems. Welding Inspection Madison. With each other, these devices make it possible for welding inspectors to adequately examine weld high quality, ensuring safety and dependability in different applications throughout markets

Making Certain Architectural Honesty

Welding treatments should follow well-known standards and codes, such as those defined by the American Welding Society (AWS) or the see it here International Company for Standardization (ISO) These guidelines ensure that the welds can hold up against operational stresses and ecological elements. Qualified and certified welders play a critical function in this procedure, as their know-how guarantees that strategies are used correctly, lessening problems such as fractures, porosity, and insufficient blend.

Post-weld assessment is an additional essential component of verifying structural stability. These assessments verify that the welds satisfy the called for top quality criteria, giving guarantee of their resilience and reliability.

Conclusion

The fundamentals of welding inspection are essential for keeping the top quality and security of welded structures. By implementing key examination approaches, such as aesthetic evaluations and non-destructive he has a good point testing, possible flaws that can endanger structural honesty are identified. Qualified inspectors are crucial in guaranteeing compliance with market requirements and efficient communication amongst stakeholders. Making use of specialized tools additionally improves the inspection procedure, ultimately guarding human lives and extending the lifespan of bonded buildings.

Welding evaluation plays a critical function in ensuring the stability, safety and security, and longevity of welded frameworks.Although welding inspection is vital to ensuring the high quality and security of welded structures, it is the specific techniques employed that figure out the effectiveness of the evaluation procedure. Trick welding inspection techniques can be extensively classified into non-destructive screening (NDT) and devastating testing.Certified examiners play a crucial duty in the welding inspection process, making sure that all welds conform with rigorous sector standards and safety policies.The basics of welding assessment are crucial for maintaining the quality and safety of welded structures.

Report this page